Heavy Truck & Equipment Diesel Filters | How To Keep Them Cleaner, Longer

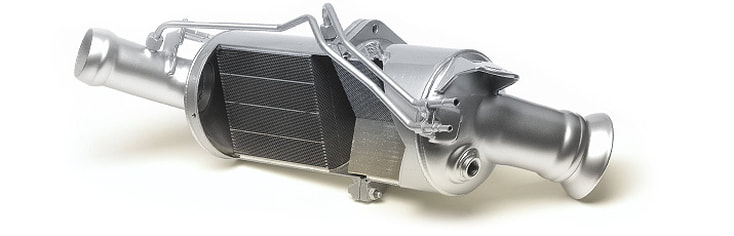

Of the various factors that diesel drivers must consider, one of the most important is how to extend the life of their diesel particulate filter (DPF). As a critical component of any modern-day diesel vehicle, the DPF's performance must be maintained to keep emissions under control.

Many drivers underestimate the importance of regular DPF maintenance. A neglected DPF can quickly become clogged with soot, leading to reduced engine performance and a damaged filter that needs to be replaced. And the last thing you need on a tight schedule is unexpected downtime. Fortunately, a few tips and solutions are available to help diesel drivers get the most out of their DPF. Let’s look at the DPF closer - and some tips to help you stay on the road longer. What are the benefits of diesel fuel conditioners?

If you own or use a heavy-duty diesel vehicle and your days are spent driving it around, chances are you want to maximize the efficiency and output of its engine. While there are many small things you can do to help out with that – even making sure your tires are properly inflated can have a positive effect – one of the biggest contributors is simply putting the right stuff into the engine in the first place. Low-sulphur diesel is just the start. Do you know about the benefits of adding a conditioner to your fuel system?

DFS910 | Diesel Fuel Service 910

One of the hardest parts of owning a diesel vehicle is making sure that all of the parts of your fuel system stay clean, and that your filters are catching all the particulates from the exhaust. With variable quality of diesel fuel and off-the-shelf filters, and many different factors contributing to engine performance, there may be plenty of soot, precipitate, and other fine particulate matter accumulating in your engine. We see a lot of it in the diesel engines we work on – so we made sure we can fix the problem at the source.

DEFs and California Truck Regulations There’s a misconception that being a trucker is easy – that you just get comfy and drive around in the sunshine, with your favourite music playing and the wide open road ahead. And while it has moments like that, it’s still a job. A job that’s done in all conditions, rain or shine, with long stretches away from home and your family. A job with rules, laws, safety protocols, and plenty of paperwork that follows you everywhere you go.

Government regulation of the trucking industry varies across provinces and states, with some being stricter than others on things like maintenance, scheduling, and emission standards. California is well known for being among the strictest places in North America when it comes to these laws, and has been for many years. 2018 Canadian Positive Air Shutoff System RegulationsBig trucks can mean big business – and with that can come some intense regulations that helps keep the drivers and the public safe. As technology gets better and more capable, regulations can change from year to year, and it’s in everyone’s best interest to keep up with the latest laws and equipment requirements.

As of January 12, 2018, new government regulations will come into effect regarding the presence and use of positive air shutdown systems in diesel engines. While these systems are already mostly in place for trucks that come into contact with atmospheric gaseous hydrocarbons, many of them are still either manually activated, or automatically reset after they have been used. The new rules target this specifically: only trucks and equipment that may come into contact with hazardous gaseous hydrocarbons will be required to have positive air shutdown systems, and furthermore, they must automatically activate in the event of an engine runaway and remain on until they are manually reset. All Class 2 & 3 chemical haulers must be equipped with RPM controlled manual reset positive air shutoff systems. |

|

What Sets Us Apart

• Service Trucks & Mobile Service • 5 Laptops & 1 North American automotive scanner • Commercial Vehicle Inspection Programs • Fleet Maintenance • Trailer Shuttles • Open 6 days a week |

RSS Feed

RSS Feed