Heavy Truck & Equipment Diesel Filters | How To Keep Them Cleaner, Longer

Of the various factors that diesel drivers must consider, one of the most important is how to extend the life of their diesel particulate filter (DPF). As a critical component of any modern-day diesel vehicle, the DPF's performance must be maintained to keep emissions under control.

Many drivers underestimate the importance of regular DPF maintenance. A neglected DPF can quickly become clogged with soot, leading to reduced engine performance and a damaged filter that needs to be replaced. And the last thing you need on a tight schedule is unexpected downtime. Fortunately, a few tips and solutions are available to help diesel drivers get the most out of their DPF. Let’s look at the DPF closer - and some tips to help you stay on the road longer. What Is A Diesel Particulate Filter (DPF)?

Diesel engines have undergone significant advancements in terms of efficiency and power. However, these engines also produce substantial particulate matter, contributing to air pollution.

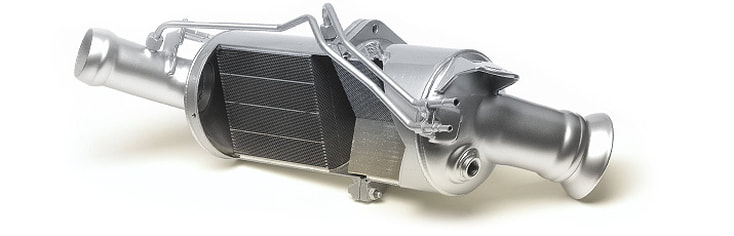

Diesel engines are now equipped with a universal component called a diesel particulate filter (DPF) to help trap and remove harmful particulate matter from the exhaust gases. As the exhaust gases pass through the DPF, the particulate matter is captured, allowing clean air to be released into the environment. However, nothing works perfectly! Over time, the DPF becomes filled with trapped particulate matter and becomes plugged up. This accumulation of particulate matter reduces the efficiency of the DPF and can negatively impact the vehicle's performance. What is DPF Regen?

DPF Regen (regeneration) involves converting soot in a DPF into ash using heat, chemicals, or electricity. Soot combustion temperatures vary from 250˚C – 350˚C with a catalyst to around 550˚C without one.

DPF regeneration is essential to prevent clogging, which hampers engine performance. There are three primary regeneration methods: Passive Regen This natural process happens while driving when exhaust gases are hot enough to burn off the soot. A warning light might appear if ineffective due to conditions like stop-and-go driving. In such cases, the driver should avoid parking on flammable surfaces and continue driving. Active-Only Regen Less common and typically seen in retrofit systems. Here, diesel fuel or electricity is used to burn the soot. This is usually initiated by the driver while parked. Passive-Active Regen Most trucks use this method, allowing for natural regeneration while driving and driver-initiated forced regen. Forced regen might be necessary after extended traffic jams, indicated by a "service DPF" light. Why You Must Identify DPF Issues Early

It is crucial to recognize that removing a DPF from an engine is illegal in many places, with an increasing number of provinces enacting laws to prevent such removal. The installation and maintenance of DPFs are mandated to control air pollution and ensure that diesel engines meet emissions standards.

Early detection of DPF issues is essential for multiple reasons. 1. Prevent costly repairs down the road Identifying any potential DPF issues can help prevent costly repairs and replacements. Catching DPF problems early allows for timely intervention and prevents further damage to the DPF and other engine components, saving money in the long run. 2. Maximize engine performance Early detection of DPFs allows for optimization of engine performance and fuel efficiency. Clogged filters reduce acceleration and responsiveness, leading to longer distances between fill-ups. 3. Keep your diesel vehicle moving for longer Addressing DPF issues promptly helps maintain the reliability of the vehicle. A malfunctioning DPF can lead to decreased engine performance, increased fuel consumption, and potential breakdowns, causing inconvenience and costly downtime. To improve the life and reliability of DPFs, companies like West Tech Mobile offer heavy truck computer diagnostic equipment. This advanced equipment allows for accurate and efficient diagnosis of DPF-related issues, enabling timely repairs and maintenance. What Factors Affect DPF Life and Reliability?

Several factors can affect the life and reliability of a DPF. Driving conditions play a significant role, with city driving and frequent cold engine starts increasing the chances of DPF issues.

In stop-and-go traffic, the DPF may not reach the required temperature to effectively regenerate and clean itself, leading to particulate matter buildup. Starting the engine from a cold state prevents the DPF from reaching optimal operating temperatures quickly, increasing the likelihood of clogging. To mitigate these issues, it is recommended to plug in the truck or use a coolant heater during cold weather. By keeping the engine warm, these measures help maintain the optimal temperature for DPF regeneration and prevent unnecessary wear on the DPF. Remember to avoid idling the truck for an extended period to warm it up, as this can lead to faster clogging of the DPF. When the DPF is clogged, the truck must go through its regeneration cycle or require manual cleaning. If not addressed promptly, it can lead to higher exhaust gas temperatures, reduced engine performance, increased fuel consumption, and other costly repairs. 6 Preventative Maintenance Tips for Extending DPF Life

Taking proactive measures to maintain the DPF can significantly extend its life and optimize its performance. Here are some preventive maintenance tips:

Innovations and Solutions for Extending DPF Life

Innovations and ongoing research in filter design aim to extend DPF regeneration intervals. Filter designers are experimenting withnew designs and materials to enhance the efficiency and longevity of DPFs. Additionally, fuel additives such as Viscon have shown promise in extending regeneration intervals. This ensures that the DPF is cleaned more effectively and efficiently.

In addition to product innovation, technological advancements are also helping to extend the life of DPFs. Predictive analytics and remote monitoring systems allow technicians to diagnose issues early on and provide effective preventative maintenance solutions. These technologies help reduce unplanned downtime and can save organizations time and money in the long run. For instance, West Tech Mobile has introduced a cutting-edge machine capable of thoroughly flushing and cleaning the EGR, injectors, and all after-treatment components, including ECR, DOC, and DPF, without the need to remove these parts. This process involves using two pails of a special alkaline solution pumped through the intake system. This procedure, taking approximately 5 hours, allows for effective cleaning while the engine is running, showcasing a significant advancement in diesel engine maintenance and care. Frequently Asked DPF Questions There are a variety of ways to extend DPF life. These include experimenting with new designs and materials, using fuel additives such as Viscon to enhance regeneration intervals, and leveraging predictive analytics and remote monitoring systems for early diagnosis of issues. Typically, the life expectancy of a DPF system is between 100,000-150,000 miles (161,000-241,500 kilometers) However, this can vary depending on environmental conditions and how often preventative maintenance is performed. Regular cleaning and inspections can help to extend its lifespan. A DPF can typically be regenerated between 200-400 times, depending on the size of the filter and the amount of soot buildup. A qualified technician should only perform the regeneration process to ensure that it is done safely and correctly. Yes. If a DPF has become blocked with soot, it can be reconditioned by being cleaned using specialist equipment. This will help to restore the filter's performance and extend its lifespan, saving you from having to replace it prematurely. However, this should only be done by an experienced technician, as incorrect cleaning could cause further damage to the filter. Keep Your Vehicle Moving with West Tech Mobile in Calgary

Extending the life of the DPF is crucial for cost savings and maintaining the reliability of diesel-powered vehicles. By implementing preventive maintenance tips and considering innovative solutions, vehicle owners can optimize the performance of their DPFs, reduce the risk of costly repairs, and contribute to a cleaner environment.

West Tech Mobile is Calgary’s leading full-service mobile diesel maintenance and repair provider. Our experienced technicians specialize in preventive care, repairs, diagnostics, and DPF services for all makes and models of diesel vehicles. We are committed to providing cost-effective solutions that help reduce downtime so your fleet can stay on the road. Contact us today to set up a service appointment or to learn more about our preventative maintenance packages. Learn More Today |

|

What Sets Us Apart

• Service Trucks & Mobile Service • 5 Laptops & 1 North American automotive scanner • Commercial Vehicle Inspection Programs • Fleet Maintenance • Trailer Shuttles • Open 6 days a week |

RSS Feed

RSS Feed