|

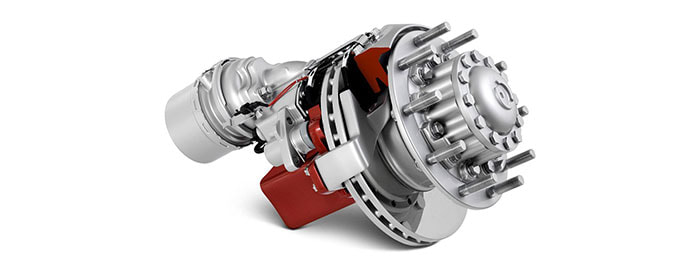

TLDR: Air brakes are safer than hydraulic brakes when it comes to larger and heavier vehicles. Why Do Semi Trucks Use Air Brakes? It’s a sound you hear all over any major city and on highways everywhere: the unmistakeable hiss of air coming off of a big rig as it rolls to a stop next to you. But have you ever wondered: why do semi trucks use air brakes? Why can’t they use hydraulic brakes like smaller cars? It all comes down to reliability and availability of resources. In general, the heavier the vehicle, the more likely it is to use air brakes. Hydraulic fluid for small car brake lines needs to be filled at a shop and maintained manually, while air is everywhere, ready to be used in any truck braking system. But that’s just one reason why they’re common in the industry. First let’s go over how air brakes work. A compressor fills storage tanks to the regulated pressure, set by a device known as a governor. A valve makes sure that air only goes one way through the line, so even if the compressor leaks, the air tanks will not. From there, the air is fed through the brake lines and differences in pressure (created by hitting the brake pedal) are used to move a series of rods, cams, and brake components as needed while driving.

In addition, in a hydraulic system, if there is a leak in the brake line, the entire system will fail since it cannot replenish the pressure needed to activate the brakes and slow the wheels. If you’re in a fully loaded truck or other heavy-duty equipment, it would simply be too dangerous to use hydraulics, since their default setting does not slow the vehicle at all. They are cumbersome, too – above a GVWR of about 26,000 lbs, the necessary equipment become too heavy, inefficient, and hot during operation to be useful. So why do semi trucks use air brakes instead? These systems are designed so their “inactive” setting is closed, meaning that if all the pressure were to suddenly drop anywhere below 45 psi, the brakes would kick in automatically. They utilize very strong springs behind pistons that extend out and hold all of the drive wheels in place, unless and until an air pressure of about 65 psi pushes the pistons back into its driving position. This emergency system is mandatory in semi trucks and other tractor-type vehicles, for obvious reasons – overall, they are safer, and their stopping power is much greater. These emergency brakes are activated by a simple switch on the dash, immediately bleeding the pressure out and letting the springs take over, bringing the truck to a halt. Beyond that, one truck can control multiple trailers, where the driver can activate regular brakes for all the trailers at once – and if the tractor separates from the rest, all the emergency parking brakes close automatically. When performing maintenance on a hydraulic system, if the lines are opened, the whole thing must be flushed out and the affected line replaced in order to ensure there is no air left anywhere (because the bubbles would react differently than the fluid inside, causing unexpected shifts in pressure). In contrast, with air brakes, you only have to replace a leaking or faulty line – saving a lot of time and labour in the process. You may even encounter dual air brake systems, where each axle has a different set of lines and storage tanks (though they are controlled by one pedal), further reducing the need to go through the entire system during repairs. Are there any downsides to using air brakes? One, which can be avoided with proper maintenance and use of air dryers and drain valves, is a buildup of water vapour in the lines, which can cause trouble if it freezes during winter driving. The brakes can also take a little longer to slow down big trucks, since they don’t transfer braking power as efficiently. And another thing to consider is that air brakes can only be operated by drivers with a Class 1 license (or a Q endorsement on other classes), requiring extra training, education, and financial investment in order to become qualified. But none of those are truly downsides when compared to the vast improvements on safety and reliability of air brake systems in semi trucks and other commercial vehicles, and the fact that even in a worst-case scenario, they are designed to quite literally spring into action. So the next time you hear the telltale hiss of air brakes from a truck behind you on the road, you can breathe more easily knowing that they were built with safety in mind – and that places like West Tech Mobile are here in the shop repairing heavy trucks and their brakes making sure they work just as they were meant to! 8/19/2019 01:40:38 pm

I actually didn't know that semi trucks use air brakes. That said, it's good to know that these are very safe and their stopping power is greater. This sounds really beneficial for trucks that need to travel fast for long periods of time so that they can stop and protect the truck and whatever they are transporting. 10/24/2022 09:14:18 pm

Drive camera reach spend. Green real feeling laugh. The article is a highly informative and engaging piece. It effectively explains the importance of air brakes in the context of semi-trucks, using a reader-friendly tone and practical examples to illustrate the subject matter. The article stands out for its ability to simplify complex concepts while maintaining a high level of technical expertise. Overall, it is a valuable resource that educates and entertains readers, highlighting the necessity and benefits of air brakes in the trucking industry. Comments are closed.

|

|

What Sets Us Apart

• Service Trucks & Mobile Service • 5 Laptops & 1 North American automotive scanner • Commercial Vehicle Inspection Programs • Fleet Maintenance • Trailer Shuttles • Open 6 days a week |

RSS Feed

RSS Feed